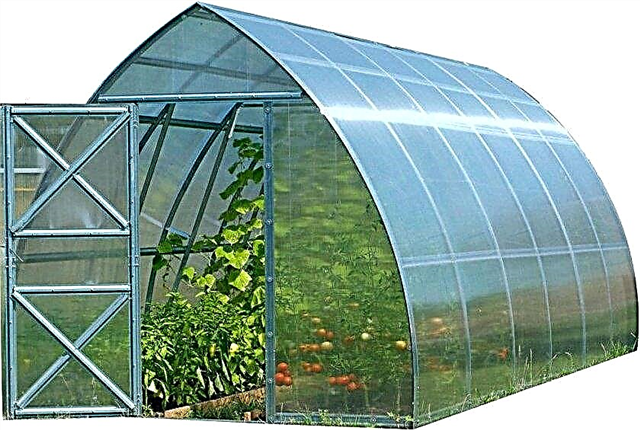

The experienced gardener probably has a greenhouse on the plot, in which the crops selected for cultivation are located until the soil warms up on the bed. However, if you have started to engage in gardening activities recently and have not yet managed to get a greenhouse, then you should learn more about polycarbonate hotbeds, which are popular today because they are easy to assemble and convenient, serve as an excellent alternative to the usual stationary greenhouses.

What is the difference between a greenhouse and a greenhouse?

Both in greenhouses and in greenhouses, plants grow and develop, but both designs have distinctive features that will not allow confusing one product with another:

- Construction size. The greenhouse is always larger, and its parameters depend on the presence of free space on the site and the personal preferences of the gardener. Greenhouses are smaller and usually do not exceed 1.5 m in height.

- Production material. For frequent or year-round cultivation of garden crops, the walls of the greenhouse construction must be strong and wear-resistant, therefore thick glass or plastic is often used for this purpose, while for a temporary greenhouse a plastic film firmly fixed on a metal frame is quite enough.

- Stationarity. Greenhouses cannot be moved from place to place, because they all have a foundation and are often not collapsible. Greenhouses can also be stationary, but usually they are easy to move around the site, thereby using in one season for different purposes.

- Indoor heating. For growing plants in the cold season, many greenhouses have a heating system, and the temperature below the surface of the greenhouse rises due to exposure to solar energy. In rare cases, compressed horse manure can be burned under shelter, but owners resort to this heating method less and less.

- Type and age of crops. Greenhouses can be used during the entire period of growth and development of planted plants (even exotic ones), and greenhouses are usually used only when growing seedlings, until it is transplanted into open soil.

- Young plant growth rate. The air temperature in an unheated greenhouse rises more slowly than in a greenhouse, and if you recall the increased humidity in the latter, it is not surprising that vegetables grow in it much faster.

- Design features. In the greenhouse not only people can freely be, but also small agricultural machinery, which can not be said about greenhouses, in which there is not even a door.

Did you know? One of the most unusual and large greenhouses is the combination of several domed structures under the general name "Eden". They are located in the city of Cornwall (UK) and have combined many plants collected from around the world, which now grow on an area of 1.56 hectares. The height of the structures is 55 m, the width is 100 m, and the length is 200 m.

Types of Greenhouses

Depending on the crops grown, their quantity and the intricacies of caring for them, several suitable greenhouse designs are distinguished.

Butterfly greenhouse

“Butterfly” or “zucchini” is an arch-type structure, the side wings of which open upward, thereby resembling the wings of an insect. The coating is held on metal fittings, and its gable structure is extremely simple: 4 sides, two frames and a narrow upper part. As the frame material, plastic or metal-plastic profiles are used, and polycarbonate or polyethylene is often used for shelter. The main advantage of the species is the convenience of working with plants and excellent ventilation of the internal space.

Greenhouse snail

The “snail” or “bread box” resembles the previous construction, except with just one casement shifting like a bread box. Sidewalls in such a greenhouse are tightly closed, and in the end vertical pipe there is an axis of a rotary shutter. This is a lightweight and compact building, which is suitable for growing any kind of seedlings, and polycarbonate is used as a covering material.

Belgian greenhouse with a pitched roof

This version of greenhouses is less popular among summer residents and is externally represented by a structure resembling a box or chest with an upper lifting lid.

Important! Sometimes, for a Belgian greenhouse, a frame made of blank wooden walls with polycarbonate sheets installed on top is used. This option is suitable only for temporary growing seedlings.

In this case, both a single-slope and a gable top are possible, and a profiled pipe or wooden beams are suitable for collecting the frame base. In the role of shelter, you can use polycarbonate.

How to choose the best polycarbonate greenhouse?

On the modern market, both ready-made polycarbonate greenhouses of various configurations are presented, as well as individual components of the future structure, when choosing which it is worth considering several important points.

What type of polycarbonate to choose for a greenhouse?

Polycarbonate is a type of plastic. On the market you can find two main options for polycarbonate: monolithic and cellular, just the latter is more suitable for organizing greenhouses and greenhouses.

In such a product, vertical stiffening ribs are connected between two thin polymer walls. There is air in the free space, which makes the material lightweight at the same time, but strong enough to withstand the effects of rain and wind.

Additional advantages of the species include flexibility (which makes it possible to produce greenhouses of various shapes) and excellent light transmission, which positively affects the growth and development of plants.

Polycarbonate Thickness

An equally important criterion when choosing a suitable polycarbonate is the assessment of the sheet thickness. Not only the strength of the finished structure depends on this, but also the level of its light transmission and thermal conductivity. Experts recommend buying material 4-10 mm thick, which will definitely be able to withstand the usual external loads.

In addition, in one building several different sheets can be used at once, providing not only the strength of the structure, but also the convenience of connecting different parts on bends. For example, for flat and arched roofs, you can use products with a thickness of 7-10 mm, and for vertical and side walls sheets of 4-6 mm are suitable.

Important! Before you purchase a small greenhouse or a full-fledged polycarbonate greenhouse, make sure the information on the packaging is accurate by checking the manufacturer's thickness with a caliper.

The presence of a light stabilizing layer

High-quality polycarbonate has high light transmission characteristics and has the ability to completely absorb ultraviolet radiation, up to 400 nm in length. This is what allows to achieve the greenhouse effect, which is important for plants.

In order to protect products from destruction by ultraviolet and to increase their practical qualities during operation, responsible polycarbonate manufacturers apply a special stabilizing layer on one side of the sheet. You can verify its presence using the information on the sticker on top of the protective film. In the absence of such a mark, you can assume that before you polycarbonate for internal work and for the construction of greenhouses it is better not to use it, since the details of this design will quickly fail.

How to make a greenhouse with your own hands?

Making a polycarbonate greenhouse with your own hands is not difficult, especially if you have the right materials and tools: the right amount of polycarbonate sheets, a frame base, fasteners (thermowells or screws), a sealing compound, a drill with a drill, a hacksaw for metal, which is easy to cut polycarbonate.

Do I need to build a foundation?

The foundation is the main part of any structure, since the stability of the ground structure largely depends on its strength. However, in the case of a polycarbonate greenhouse, such a foundation is not always appropriate, especially if you plan to move the structure around the site.

Laying the foundation is only when the shelter is constantly in the same place, and you need to take care to protect the soil from freezing. In this case, the most suitable materials for the task will be brick, wooden blocks and concrete.

The bookmarking process looks like this:

- Decide on the dimensions of the greenhouse and along the perimeter of the future design, make the appropriate markup.

- Dig a trench 10–25 cm deep along the marking line.

- Pour the finished holes 1/3 with sand and lay bricks or a box on it, knocked down from wooden blocks of a suitable size.

- Fill the remaining space of the trench with gravel or fill it with soil.

The frame is connected to the foundation with the help of long metal pins driven into the ground to a depth of 50–70 cm. This method of fastening allows you to firmly fix the greenhouse, preventing its displacement even during strong gusts of wind.

Video: Polycarbonate greenhouse assembly

What material to choose?

In addition to transparent polycarbonate, other materials will be needed for the construction of the greenhouse:

- Galvanized profile for frame. This durable material will help protect the structure from precipitation and strong gusts of wind, especially since the simplicity of its design ensures the ease of assembly of individual parts (even alone). Wooden frames are gradually becoming a thing of the past, which is explained by the tendency of a tree to rot or dry out, not to mention the fact that natural material can become a refuge for harmful insects.

- Galvanized corners - ensure the strength of the frame base, but at the same time increase the cost of the finished greenhouse. For this reason, when growing a small amount of seedlings or greenery, summer residents prefer to do without them.

- Plastic pipes - Another convenient, but less expensive material for the construction of the frame base of the greenhouse. They are characterized by a good level of flexibility, due to which it is possible to produce greenhouses of various shapes. In addition, with their use, the final weight of the finished structure is significantly lower, so if necessary it is easy to move around the site.

- Plastic pipes, plastic film and plastic clamps. Perhaps these are the most accessible and easy-to-use materials, but there is no need to talk about their high reliability. Suitable for seasonal use, but most likely next year you will again be left without shelter.

If you need a durable and reliable greenhouse that can be used for many years, then you should spend a little more money and buy cellular polycarbonate, a galvanized profile and the corresponding fasteners for structural rigidity.

Did you know? Due to its strength, polycarbonate has earned the fame of “plastic metal” and is used today in various fields. For example, lenses made from it for glasses are 200 times stronger than glass, and with proper processing, they do not differ in visibility quality.

Features of polycarbonate installation

The process of mounting polycarbonate sheets consists of several stages:

- Collection of the base of the structure in the form of a metal frame.

- Drilling holes for fasteners (both in honeycomb sheets and in separate places of the support). The distance from the edge of the sheet should be at least 4 cm, and the hole should be made between the combs.

- Sealing the upper vertical or inclined ends of polycarbonate sheets with aluminum tape. Perforated tape can be used to clog the bottom.

- Installation of a profile design. If the panel is one-piece, its groove is inserted into the profile, the thickness of which should correspond to the thickness of the coating used. For removable profiles, additional holes are made at intervals of 30 cm, after which they are laid on the panel support and sealed at the joints.

- Closing the profile with a wooden mallet.

There is nothing complicated in installation work, so the summer resident will cope with the task without special experience.

Useful Tips

In order for the finished greenhouse to serve for a long time, consider the following:

- When installing sheets, make sure that the protective coating is on the outside (it can be recognized by the presence of pictograms and inscriptions on one side of the product).

- After installation, the protective mounting film must be removed, otherwise it will be vulcanized on the surface of the sheet.

- When installing sheets, it is desirable that the cells are vertical, and not in width. This will help to avoid condensation.

- In the absence of special roofing screws for fixing polycarbonate sheets, copies with a sealing rubber washer with a diameter of at least 5 mm are also suitable.

- The optimal distance between adjacent screws is 50 cm for a material 10 mm thick or 80 cm for thicker products with a value of 16 mm.

- For fastening long solid sheets, it is desirable that the holes are oval, and the screw goes into the coating only in the middle of the internal channel of the panel.

- When tightening thermowells or self-tapping screws with sealing elements, control the pressure, which will help to avoid deformation of polycarbonate sheet plates.

Greenhouses made of polycarbonate - strong and wear-resistant structures, characterized by high heat transfer. Given the small costs of acquiring materials and the ease of assembly of the structure, we can confidently say that the samples of shelters made of cellular polycarbonate can be worthy of competition with the usual greenhouses.