Pine nuts are extracted from the fruits of cedar pine, colloquially called Siberian cedar. From a mature cone, dried in the sun, they fall out on their own. But to speed up the process, additional mechanisms are used. The resulting nut raw material is sieved through a sieve to remove fine debris. In the article you will find information on how to make a sieve for a cedar core with your own hands.

How to make a do-it-yourself sieve for pine nuts

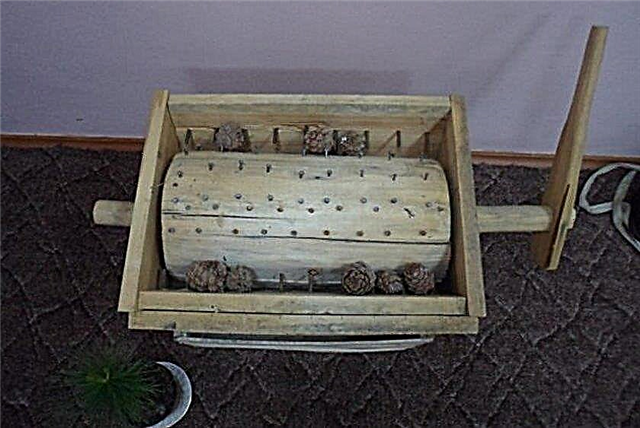

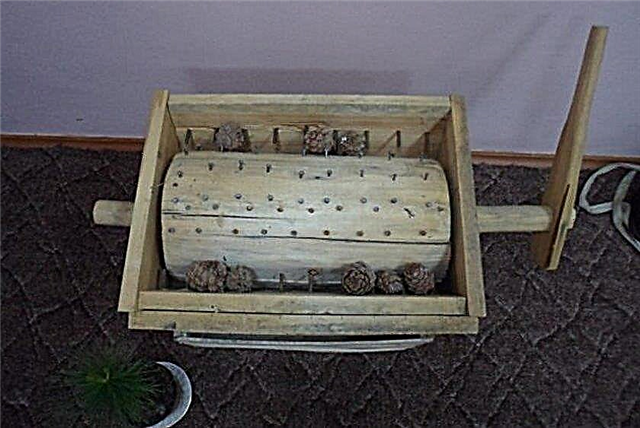

The main task of the pine nuts collector is to chop a cone to get grains. If you install on top a drum that grinds, and in the lower part of the structure provide holes equal in size to the cores, then they will immediately be able to be separated from the large scales of the cones.

Important! Pine cones need to be collected with gloves, because they have a hard-to-wash resin, and you will get your hands dirty.

The main ways to get the kernel out of the bumps:

- Twist it in your hands and thus shake the nuts out of it. This is the easiest and most inexpensive way. But this way you can process a small amount of well-dried raw materials.

- Mechanical friction helps speed up processing. If there are a lot of cones, then crushers are used for this. The simplest one is similar to the ruble used to wash clothes in antiquity. The principle of operation is simple: a bump is between two corrugated boards, frayed, and nuts are poured into a framed bowl or bucket. A typical crusher consists of a box, inside of which a drum with corrugated faces rotates, and at the bottom there is a mesh sieve with holes in which the crushed parts of the cone and core are poured.

Then the obtained raw material is sieved through a sieve, similar to an ordinary kitchen. It is necessary to weed out small debris, remove and separate large scales of the cone and the kernel of nuts.

Important! Never peel pine nuts until you are ready to eat them. The oils contained in them react with air, resulting in a rancid taste.

What can be done

You can make a crusher from improvised materials.

The design will consist of:

- wooden or metal case;

- a wooden drum, on the surface of which grooves are made 1.5–2 cm wide and up to 1 cm deep;

- sieves.

The rotation of the drum occurs with the handle. Its corrugated surface clamps the bump between itself and the body wall. As a result, crushing occurs. The sieve is made of a metal sheet in which holes of the desired diameter or mesh are made. If the sieve is not a part of the crusher, but a separate structure, then the sides are attached to the sides so that it is convenient to load the raw materials and shake it.

Grid Size and Hole Diameter

The sieve may be one or more. The size of the cedar core is 5–9 mm. So, the first should have cells with a diameter of 6–10 mm. This will allow the nuts themselves and small debris to slip through it. Large impurities will linger here. If you use one more, with 3 mm cells, you will get pure nuts at the exit without the remains of flakes from the cones.

Did you know? The darker the shell of a pine nut, the higher its quality.

Step by step instructions

Given that the cones are different in size, and they are smaller on young trees, you can assemble the structure so that its dimensions can be customized.

For this:

- Measure the exact dimensions of the drum.

- Draw a schematic drawing of the body in the form of a trapezoid.

- A drum will be installed in its lower part. There should be a distance of about 3-4 cm between it and the walls. Provide about 10 cm between it and the bottom and the same distance in the upper part of the structure.

- Assemble the case from parts of the board cut to the calculated dimensions.

- Fasten the drum into the housing.

- To ensure rotation, attach a handle to the drum from the outside of the structure.

- Instead of the bottom, attach a sieve (removable metal sheet or mesh with 5-10 mm holes). Nuts will be sifted out through them.

- The whole structure can be mounted on a frame made of boards or metal. The total height will be about 70–90 cm. Those who will work with the mechanism should be comfortable standing during work, which means that the dimensions are adjusted to the height of this person.

- Under the crusher, set the container into which the nuts will be poured.

Video: DIY sieve

Sifting process

Sifting consists of the following steps:

- Cones are poured into the crusher from above. When the drum rotates, they will fall into the gap between the wall and the drum and grind.

- The resulting nuts will fall on a grid or a sheet with holes and from there they will fall into a container for collecting finished products.

- After the cores are separated from the large debris, they are sieved through a smaller sieve to separate the small debris.

- The resulting raw materials are sorted, those nuts whose shells are cracked are separated, and put into bags.

Advantages and disadvantages of this cleaning method

Grinding cones with any metal grinder speeds up the cleaning process. A crusher with a wooden drum with a ribbed surface is considered the most acceptable mechanism for extracting nuts. It does not damage the shell, which means that it helps to obtain higher quality raw materials for sale. There are no drawbacks to this cleaning method.

The design, which crushes the cones and allows you to separate the nucleus from the resulting vegetable debris during operation, should be simple, convenient and easy to move. It is also advisable to make it detachable, so that at the time the harvesting season is over, it is convenient to store it.Did you know? High-quality Mexican coffee is enriched with pine nuts to obtain an improved taste of the product. In addition, this coffee becomes much healthier thanks to this supplement.